Industrial Robotics Market to Surge from USD 55.1 Billion in 2025 to USD 291.1 Billion by 2035 | Future Market Insights, Inc.

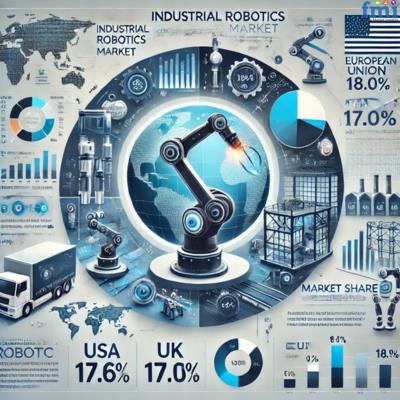

East Asia is projected to emerge as the most remunerative industrial robotics market, accounting for more than 2/3rd of the revenue share by 2025. Based on end use category, automotive and electronics industries are anticipated to collectively account for a dominant share in the global market through 2035.

/EIN News/ -- NEWARK, Del: , March 23, 2025 (GLOBE NEWSWIRE) -- The global industrial robotics market is set for remarkable expansion, with projections indicating substantial growth from 2025 to 2035. The increasing adoption of automation, advancements in artificial intelligence (AI), and the rise of Industry 4.0 are key drivers reshaping the market landscape. As industries continue to seek efficiency, flexibility, and cost savings, industrial robots are becoming integral to manufacturing and production processes worldwide.

Between 2025 and 2035, the industrial robotics market is set to witness substantial growth, driven by increasing automation across industries such as manufacturing, automotive, electronics, food & beverages, and pharmaceuticals.

The market is projected to reach a valuation of USD 55.1 billion by 2025 and is expected to expand significantly to USD 291.1 billion by 2035, reflecting a compound annual growth rate (CAGR) of 18.1%. The adoption of advanced robotics in production lines is enhancing productivity, ensuring consistent quality, and reducing operational costs for businesses.

A key trend fueling this growth is the rise of collaborative robots (cobots)—robots designed to safely work alongside humans in shared workspaces. These robots are built for precision in repetitive tasks while enhancing workplace safety. Furthermore, artificial intelligence (AI) and machine learning (ML) are revolutionizing industrial robotics, enabling AI-driven decision-making and predictive maintenance, which helps minimize downtime and extend the lifespan of robotic systems.

Another major market driver is the rising demand for flexible and customizable robotic solutions. As manufacturing evolves, companies seek robots that can be reprogrammed and adapted for different processes. This adaptability allows manufacturers to respond quickly to shifting production needs, ultimately improving competitiveness and operational agility.

Propel Your Success: Secure Sample of Our Insightful Report Now: https://www.futuremarketinsights.com/report-sample#5245502d47422d323835

Global Market Trends in Industrial Robotics from 2025 to 2035

Global Market Trends in Industrial Robotics from 2025 to 2035

The industrial robotics market is expected to witness a surge in demand due to increasing labor shortages, cost-efficiency measures, and advancements in technology. As industries strive to reduce operational costs and enhance productivity, the use of robotics is becoming more prevalent across various sectors, including manufacturing, automotive, healthcare, and logistics. The growing shift towards automation and digitalization is expected to drive innovations in robotic technology, further expanding market opportunities.

Collaborative Robots in Manufacturing Processes

Collaborative robots, or cobots, are playing a pivotal role in manufacturing by working alongside human operators. Unlike traditional robots, cobots are designed with advanced safety features, allowing them to operate in close proximity to workers without the need for safety barriers. This technology enhances productivity and workplace safety while enabling more flexible manufacturing processes. Cobots are particularly useful in assembly lines, packaging, and material handling, where human-robot collaboration can improve efficiency and reduce strain on human workers.

Artificial Intelligence Applications in Industrial Robotics

AI-powered robots are transforming industrial operations by enabling predictive analytics, real-time decision-making, and adaptive learning. With AI integration, robots can analyze vast amounts of data, detect patterns, and make autonomous decisions to optimize workflows. These intelligent robots enhance manufacturing precision, reduce errors, and adapt to changing production requirements. AI-driven robotics is especially beneficial in high-tech industries such as electronics, pharmaceuticals, and aerospace, where precision and quality control are critical.

"The rapid evolution of industrial robotics is revolutionizing automation, enabling businesses to achieve higher efficiency, precision, and adaptability. With advancements in AI, collaborative robotics, and flexible automation, industries are entering a new era of smart manufacturing that will redefine productivity and competitiveness." - says Nikhil Kaitwade, Associate Vice President at Future Market Insights (FMI).

Predictive Maintenance Using Industrial Robots

Predictive maintenance is a game-changer in industrial robotics, reducing downtime and operational costs. By leveraging IoT and AI-driven analytics, companies can anticipate machinery failures before they occur, ensuring seamless production and improved equipment lifespan. Predictive maintenance systems use sensors and data analytics to monitor the health of robotic systems, alerting operators to potential issues before they result in costly breakdowns. This approach improves reliability, enhances productivity, and minimizes unexpected disruptions in manufacturing processes.

Flexible Automation Solutions for Manufacturing Industries

The growing need for customization and agility in production lines has led to the rise of flexible automation solutions. Traditional rigid automation systems are being replaced by adaptable robotic solutions that can quickly adjust to changing production demands. With modular robotics, manufacturers can reprogram and reconfigure robotic systems to handle different tasks, increasing operational efficiency. This flexibility is particularly valuable in industries with high product variability, such as consumer electronics, automotive, and food processing.

Detailed Market Study: Full Report and Analysis: https://www.futuremarketinsights.com/reports/industrial-robotics-market

Impact of Industry 4.0 on Industrial Robotics

Industry 4.0 is accelerating the adoption of connected robotics solutions, transforming traditional manufacturing into smart factories. Smart factories leverage interconnected robotic systems, real-time data analytics, and cloud computing to optimize efficiency, reduce waste, and improve supply chain management. With advancements in digital twin technology and augmented reality, manufacturers can simulate and optimize production processes before implementation, reducing errors and improving overall productivity. The integration of robotics with Industry 4.0 principles is expected to drive significant growth in the industrial automation sector.

Adoption of Industrial Robots in Automotive Production

The automotive industry remains a dominant adopter of industrial robotics. Automated assembly lines, robotic welding, AI-assisted quality control, and autonomous material handling are streamlining production, improving precision, and reducing manufacturing costs. The push toward electric vehicles (EVs) and autonomous driving technologies is further fueling demand for advanced robotics in automotive manufacturing. Robotic systems are being used to enhance safety, efficiency, and consistency in vehicle production, making them essential to the industry's future.

Advancements in Machine Learning for Robotic Automation

Machine learning is enhancing the capabilities of industrial robots, allowing them to self-optimize, adapt to new tasks, and improve accuracy over time. With the ability to learn from data and experiences, robots can refine their operations, improve quality control, and reduce the need for constant human intervention. These advancements are particularly useful in industries requiring high levels of precision, such as semiconductor manufacturing, pharmaceuticals, and logistics. Machine learning-enabled robots can handle complex assembly tasks, detect defects, and optimize workflows for maximum efficiency.

Benefits of Integrating Cobots in Small-Scale Manufacturing

Small and medium enterprises (SMEs) are increasingly adopting cobots to bridge skill gaps and improve efficiency. Cobots offer affordability, ease of programming, and enhanced safety features, making them an attractive solution for small-scale manufacturers. Unlike large industrial robots that require significant investment and infrastructure, cobots are more accessible and can be easily integrated into existing workflows. Their ability to handle repetitive tasks, assist human workers, and improve production speed makes them an invaluable asset to SMEs looking to stay competitive in an increasingly automated world.

Role of Industrial Robots in Enhancing Production Efficiency

Industrial robots contribute to improved productivity by minimizing human errors, increasing precision, and operating at high speeds. By automating repetitive and labor-intensive tasks, robots free up human workers to focus on higher-value activities. This shift not only boosts efficiency but also enhances workplace safety and reduces the risk of occupational injuries. Robots are being used across various industries, including logistics, food processing, and electronics, to streamline operations and improve overall production output. The continued evolution of robotics technology is expected to drive even greater efficiency gains in the coming years.

With continuous advancements in robotics technology, the industrial robotics market is poised for exponential growth, shaping the future of manufacturing and automation. The widespread adoption of AI, machine learning, and Industry 4.0 technologies will further propel the industry, making automation a necessity rather than a choice for businesses worldwide. As companies continue to invest in smart robotic solutions, the industrial robotics market is expected to experience unprecedented expansion, transforming the global industrial landscape.

Heavy Engineering Solutions Industry Analysis Reports

https://www.futuremarketinsights.com/industry-analysis/heavy-engineering-solutions

Key Players:

- ABB Ltd.: A Swiss-Swedish multinational corporation leading in robotics and automation technologies.

- FANUC Corporation: A Japanese company specializing in robotics and CNC systems.

- Yaskawa Electric Corporation: A Japanese manufacturer known for its industrial robots and motion control systems.

- KUKA AG: A German company offering a wide range of industrial robots and automation solutions.

- Mitsubishi Electric Corporation: A Japanese multinational providing advanced robotics and automation systems.

- Kawasaki Heavy Industries Ltd.: A Japanese corporation with a significant presence in industrial robotics.

Key Segmentations:

Key Segmentations:

By Robot Type:

- Articulated Robots: Robots with rotary joints, commonly used for tasks requiring a high degree of freedom.

- SCARA Robots: Selective Compliance Articulated Robot Arms, ideal for pick-and-place tasks.

- Cartesian Robots: Also known as gantry robots, they operate on three linear axes.

- Cylindrical Robots: Robots with a primary cylindrical coordinate system, suitable for specific assembly operations.

-

Parallel Robots: Robots with parallel joint linkages, often used for precision tasks.

By End-User Industry:

- Automotive: Utilizing robots for assembly, welding, and painting processes.

- Electrical and Electronics: Employing robots for assembling electronic components.

- Food and Beverage: Implementing robots for packaging and processing tasks.

- Pharmaceuticals: Using robots for handling and packaging medicines.

-

Metal and Machinery: Applying robots for material handling and fabrication.

By Function:

- Handling: Robots designed for material handling and transfer operations.

- Welding: Robots specialized in various welding applications.

- Assembly: Robots used for assembling components and products.

- Dispensing: Robots for painting, sealing, and adhesive applications.

-

Processing: Robots involved in tasks like cutting, grinding, and polishing.

Have a Look at Related Research Reports of Industrial Automation

The global pallet truck market is projected to witness steady growth between 2025 and 2035 due to the continued growth of e-commerce over the coming years, increasing warehousing activities, and growing adoption of material handling solutions.

Growing demand for EMC, RF shielding, and acoustic testing across a wide range of industries will fuel the growth of the anechoic chamber market between 2025 and 2035.

The worldwide ropeways and cable cars market will experience rapid expansion in 2025 to 2035 on the back of increasing tourism, urban mobility needs, and eco-friendly transport modes.

The global industrial stackers market is expected to grow in the coming years, owing to the growing requirement of efficient material handling solutions in industrial verticals such as manufacturing, logistics, warehousing, and retail.

The global auger filler market is expected to register steady growth from 2025 to 2035 because more demand for reliable and efficient filling machines will exist in various industries.

Expectations for the robot devices industrial market to grow significantly from 2025 to 2035 - due to the growing need for automation technologies in manufacturing, increasing labour costs and demand for high-precision production processes.

According to the Non-Thermal Processing Equipment Analysis, from 2025 to 2035, the high pressure processing (HPP) equipment market will expand quickly as a result of the growing need for non-thermal food processing methods.

From 2025 to 2035, the scope of the bulk material handling system market is expected to expand steadily owing to growth of industrial automation, infrastructure development and demand for effective material handling solutions across various industries.

The sulphur recovery technology market globally is anticipated to grow at a steady CAGR over the next decade, as stringent environmental regulations, increasing industrialization, and growing demand from the oil and gas refineries remain the key drivers.

The global explosion proof equipment market grew at a moderate CAGR during the period of 2025 to 2035. It ensures personnel and asset safety while maintaining operational efficiency as the equipment is designed in such a way that there are no sparks and no ignition source in potentially flammable atmospheres - explosion is avoided.

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Distribution channels: Book Publishing Industry ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release